0102 ib03

Cov txheej txheem pwm kab noj hniav thiab daim ntawv thov ntawm kev txhaj tshuaj pwm

2024-04-18 IB

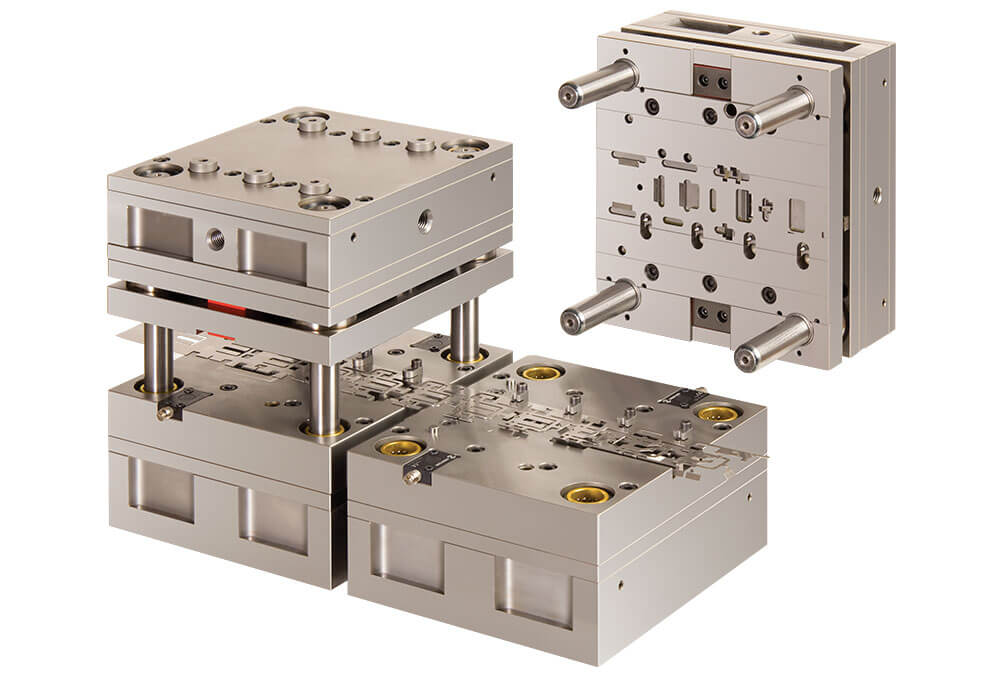

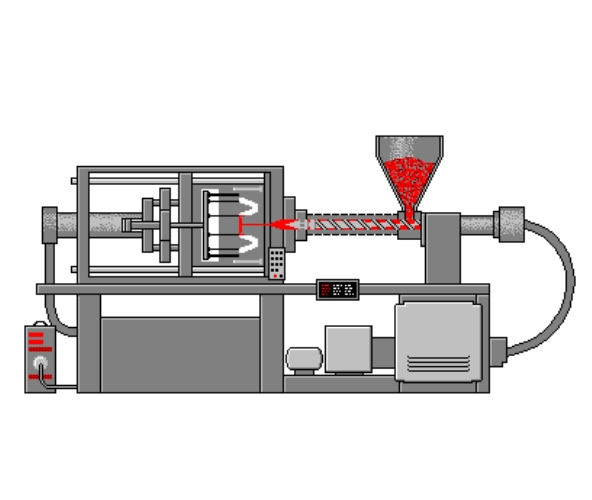

Kev txhaj tshuaj pwm yog cov cuab yeej tsim khoom yas; nws kuj yog ib qho cuab yeej uas muab cov khoom yas ua tiav cov qauv thiab cov qhov ntev meej. Vim tias txoj kev tsim khoom tseem ceeb yog txhaj cov yas yas rau hauv pwm los ntawm kev kub siab thiab kev tsav tsheb, nws tseem hu ua yas txhaj tshuaj pwm.

Cheebtsam:

1.Gating system hais txog cov yas ntws channel hauv pwm los ntawm lub nozzle ntawm lub tshuab txhaj tshuaj molding mus rau kab noj hniav. Ordinary pouring systems yog tsim los ntawm lub ntsiab channel, khiav raws, rooj vag, cov khoom txias qhov, thiab lwm yam.

2.Lateral parting thiab core rub mechanism.

3.Cov txheej txheem qhia hauv cov pwm yas feem ntau muaj cov haujlwm ntawm qhov chaw, kev taw qhia, thiab kev coj tus kheej ib sab siab kom paub meej qhov tseeb kaw ntawm qhov txav thiab ruaj khov pwm. Cov pwm clamping phau ntawv qhia mechanism muaj cov lus qhia, lub tes tsho qhia lossis cov lus qhia qhov (qhib ncaj qha rau ntawm tus qauv), tso lub khob hliav qab, thiab lwm yam.

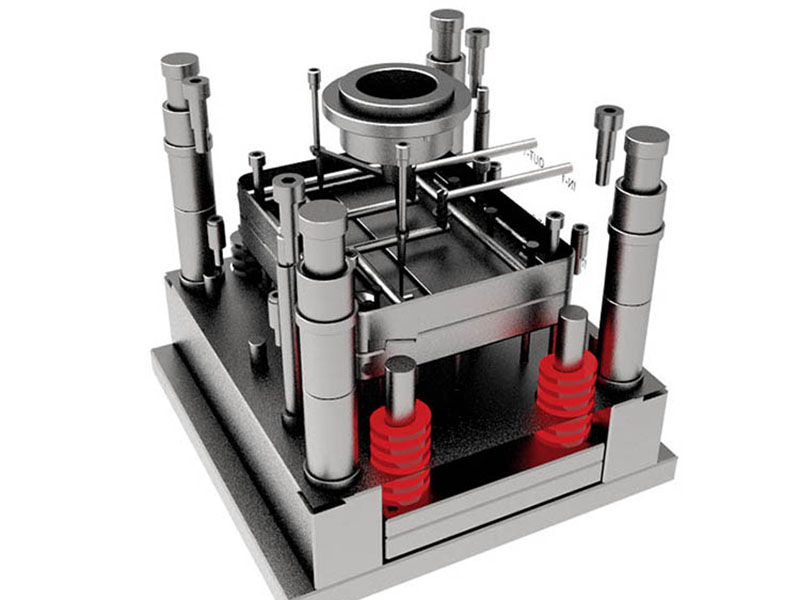

4. Lub ejection ntaus ntawv feem ntau plays lub luag hauj lwm ntawm ejecting lub workpiece los ntawm pwm, thiab yog tsim los ntawm ib tug ejector pas nrig los yog ib tug ejector raj los yog ib tug laub phaj, ejector phaj, ejector tsau phaj, ib tug reset pas nrig, thiab ib tug rub pas nrig.

5. Cua txias thiab cua sov system.

6. Cov pa system.

7. Moulded qhov chaw xa mus rau qhov chaw uas tsim cov pwm kab noj hniav. Feem ntau suav nrog: punch pwm, concave pwm, core, sib sau pas nrig, sib sau lub nplhaib thiab ntxig thiab lwm yam.

Kev faib tawm:

Txhaj pwm yog muab faib ua thermosetting yas pwm thiab thermoplastic yas pwm raws li molding yam ntxwv; Raws li cov txheej txheem molding, lawv tau muab faib ua stamping pwm tooling, hloov pwm, tshuab pwm, cam khwb cia pwm, thermoforming pwm, thiab kub nias pwm, txhaj pwm, thiab lwm yam.

Khoom siv:

Cov khoom ntawm pwm ncaj qha cuam tshuam rau cov nyhuv txias. Cov khoom siv pwm feem ntau suav nrog P20 steel, H13 steel, P6 steel, S7 steel, beryllium tooj liab alloy, txhuas, 420 stainless hlau, thiab 414 stainless hlau.

Kab noj hniav:

Lub pwm kab noj hniav yog ib qho chaw uas zoo ib yam li cov khoom molded tshuav nyob rau hauv pwm kom haum rau cov yas molten thiab tsim cov khoom tom qab siab tuav thiab txias. Qhov chaw no tseem hu ua pwm kab noj hniav. Feem ntau cov khoom me me tiav yog tsim los ua "ntau kab noj hniav pwm" rau kev lag luam thiab kev ua haujlwm zoo. Piv txwv li, ib lub pwm muaj ob peb zoo tib yam los yog cov kab noj hniav zoo sib xws rau kev tsim khoom sai.

Draft angle:

Lub kaum sab xis txheej txheem yog nyob rau hauv 1 txog 2 degrees (1/30 txog 1/60). Qhov tob yog li 1.5 degrees rau 50 mus rau 100 mm, thiab txog 1 degree rau 100 mm. Cov tav yuav tsum tsis txhob tsawg dua 0.5 degrees thiab lub thickness yuav tsum tsis txhob tsawg tshaj li 1 hli los pab txhawb pwm tsim thiab ua rau kom lub neej ntawm pwm.

Thaum ntsib qhov xav tau kev ntxhib los mos, nws raug pom zoo tias lub kaum sab xis yuav tsum loj dua li qhov xwm txheej ib txwm muaj. Lub kaum sab xis muab los ntawm nws yuav tsum zoo dua yog ntau tshaj 2 degrees, tab sis lub kaum sab xis yuav tsum tsis txhob siab tshaj 5 degrees.

Basic style:

Ob-phaj pwm yog hom pwm siv ntau tshaj plaws thiab muaj qhov zoo ntawm cov nqi qis, cov qauv yooj yim thiab luv molding voj voog.

Lub tshuab khiav ntawm peb-phaj pwm yog nyob ntawm cov khoom siv phaj. Thaum lub pwm qhib, cov khoom siv phaj ejects cov khoom pov tseg rau hauv qhov khiav thiab bushing. Nyob rau hauv peb-phaj pwm, tus khiav thiab cov khoom tiav yuav raug tshem tawm nyias.

Hom hom:

Stamping pwm tooling yog cov cuab yeej tshwj xeeb uas siv los ua cov ntaub ntawv rau hauv cov khoom txias stamping. Nws yog hu ua txias stamping tuag. Stamping yog ib txoj kev ua haujlwm siab uas siv cov pwm ntsia ntawm lub xovxwm los siv lub siab rau cov khoom ntawm chav tsev kub kom ua rau kev sib cais lossis cov yas deformation kom tau txais cov khoom xav tau.