010203

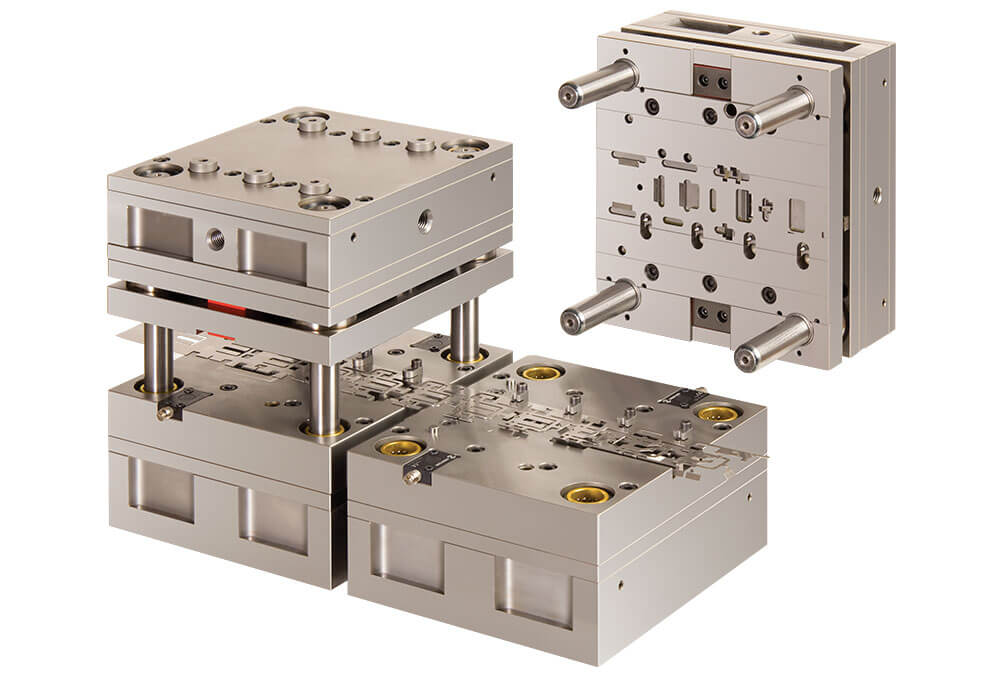

Iyo yekuumbwa mold cavity uye kushandiswa kwejekiseni mold

2024-04-18

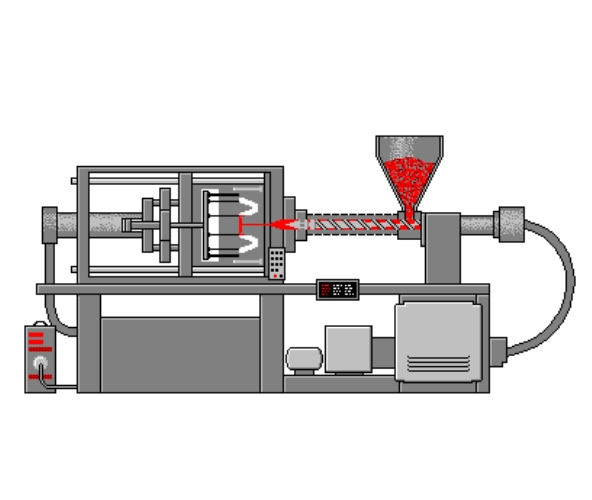

Jekiseni mold chishandiso chekugadzira zvigadzirwa zvepurasitiki; icho zvakare chishandiso chinopa zvigadzirwa zvepurasitiki chimiro chakazara uye hukuru chaihwo. Nekuti iyo huru yekugadzira nzira ndeyekubaya yakakwira-tembiricha yakanyungudutswa purasitiki muforoma kuburikidza nekumanikidza kwakanyanya uye mekiniki drive, inodaidzwa zvakare kunzi purasitiki jekiseni mold.

Chikamu:

1.Gating system inoreva mugero wepurasitiki wekuyerera muforoma kubva pamuromo wejekiseni rekugadzira muchina kuenda kugomba. Mamiriro ekudira akajairika anoumbwa nematanho makuru, nzira dzemumhanyi, masuwo, maburi emidziyo inotonhora, nezvimwe.

2.Lateral parting uye core pulling mechanism.

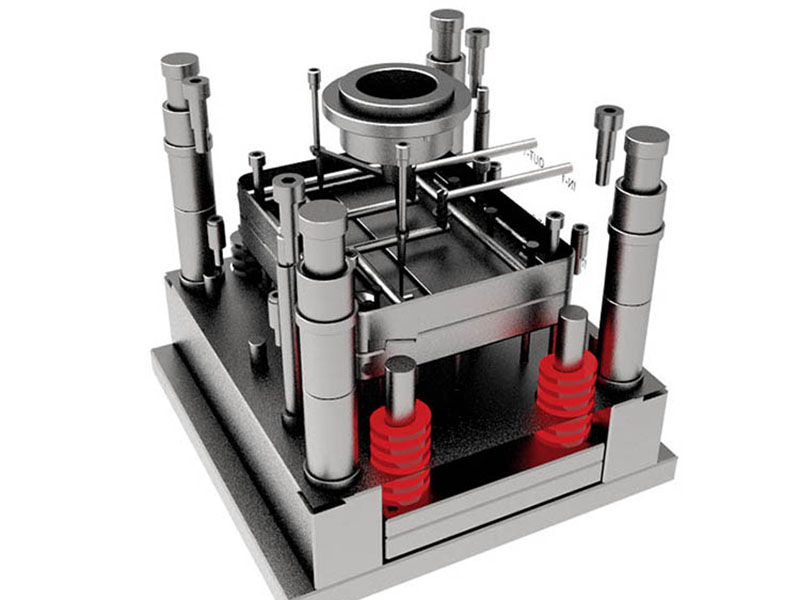

3.Iyo nzira yekufambisa muhuputi hwepurasitiki inonyanya kuve nemabasa ekugadzirisa, kutungamirira, uye kutakura imwe nzvimbo yekumanikidza kuti ive nechokwadi chekuvhara kwakanyatsovhara kwekufamba uye kugadzika molds. Iyo mold clamping dhizaini inoumbwa negwara zvigaro, giraidhi maoko kana maburi ekutungamira (akavhurwa zvakananga pane template), yekumisikidza makoni, nezvimwe.

4. Iyo ejection device inonyanya kuita basa rekubvisa workpiece kubva muforoma, uye inoumbwa ne ejector tsvimbo kana ejector tube kana push plate, ejector plate, ejector fixed plate, reset rod, uye dhonza tsvimbo.

5. Kutonhora uye kupisa hurongwa.

6. Exhaust system.

7. Miti yakaumbwa inoreva zvikamu zvinoumba gomba remuvhu. Kunyanya kusanganisira: punch mold, concave mold, core, kugadzira tsvimbo, kugadzira mhete uye kuisa uye zvimwe zvikamu.

Classification:

Majekiseni molds akakamurwa kuva thermosetting epurasitiki mold uye thermoplastic epurasitiki molds maererano kuumba hunhu; zvinoenderana nemaitiro ekuumba, iwo akakamurwa kuita stamping mold tooling, kuendesa mold, blow mold, cast mold, thermoforming mold, uye inopisa kudzvanya mold, jekiseni mold, nezvimwe.

zvinhu:

Izvo zvinhu zve mold zvinokanganisa zvakananga kutonhora. Zvishandiso zvinowanzoshandiswa zvinosanganisira P20 simbi, H13 simbi, P6 simbi, S7 simbi, beryllium copper alloy, aruminiyamu, 420 Stainless simbi, uye 414 Stainless simbi.

Cavity:

Iyo mold cavity inzvimbo ine chimiro chakafanana neyakaumbwa yakasiiwa muforoma kuti igamuchire purasitiki yakanyungudutswa uye kuumba chigadzirwa mushure mekumanikidzwa kubata uye kutonhora. Nzvimbo iyi inodaidzwa zvakare kuti mold cavity. Kazhinji zvidiki zvakapedzwa zvigadzirwa zvakagadzirirwa se "multi-cavity molds" nekuda kwehupfumi uye kushanda nesimba. Semuyenzaniso, mold ine akati wandei akafanana kana akafanana firimu cavities kukurumidza kugadzirwa.

Draft angle:

Yakajairika mwero dhizaini angle iri mukati me1 kusvika 2 madhigirii (1/30 kusvika 1/60). Kudzika kunenge 1.5 madhigirii 50 kusvika 100 mm, uye anenge 1 dhigirii 100 mm. Mbabvu haifanirwe kunge iri pasi pe 0.5 madhigirii uye ukobvu haufanire kunge uri pasi pe1 mm kuti ufambise kugadzirwa kwe mold uye kuwedzera hupenyu hwemuumbi.

Paunenge uchisangana nechido chekugadzirwa, zvinokurudzirwa kuti kona yacho inofanira kuva yakakura kudarika mamiriro ezvinhu. Kona yakapihwa nayo inofanirwa kunge inopfuura madhigirii maviri, asi kona haifanire kunge yakakura kupfuura madhigirii mashanu.

Basic style:

Iyo mbiri-plate mold ndiyo inonyanya kushandiswa mold type uye ine zvakanakira mutengo wakaderera, chimiro chakareruka uye pfupi kuumbwa kutenderera.

Iyo inomhanya sisitimu yetatu-plate mold iri pane iyo material plate. Kana mold yakavhurwa, iyo material plate inobvisa tsvina mumumhanyi uye bushing. Mune matatu-plate mold, mumhanyi uye chigadzirwa chakapedzwa chichabudiswa zvakasiyana.

Mhando dzakajairika:

Stamping mold tooling ndeye yakakosha maturusi emidziyo inoshandiswa kugadzirisa zvinhu kuita zvikamu mukutonhora kwekutsika. Inonzi cold stamping die. Stamping inzira yekumanikidza inoshandiswa inoshandisa mold yakaiswa pane yekutsikirira kuisa kumanikidza kune izvo zvinhu pakamuri tembiricha kukonzeresa kupatsanurwa kana deformation yepurasitiki kuwana zvikamu zvinodiwa.