010203

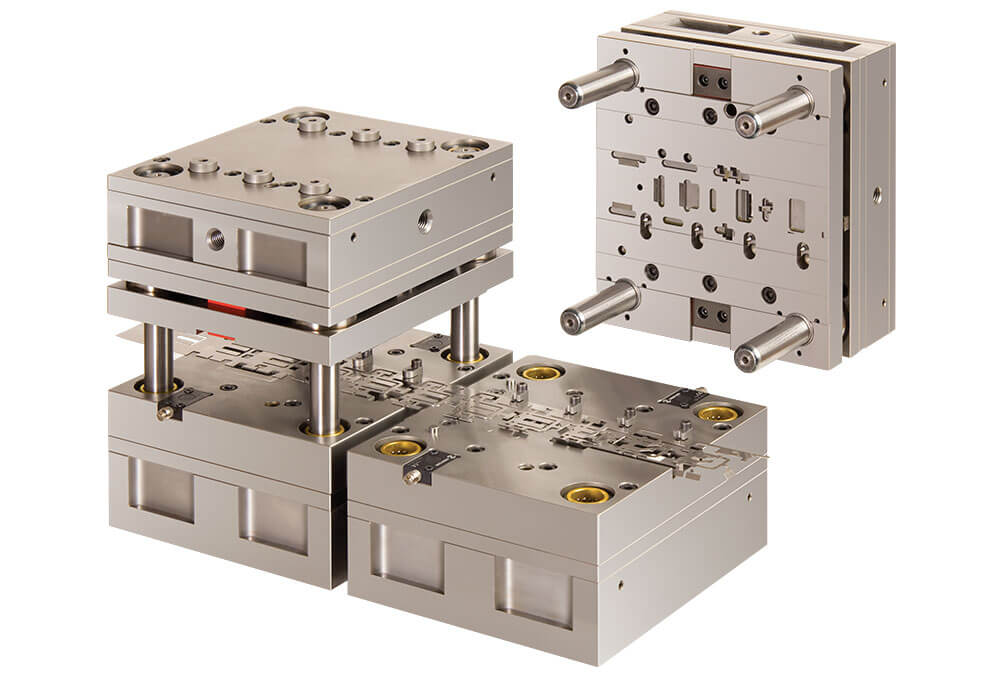

Ukubunjwa kwe-mold cavity kunye nokusetyenziswa kwe-injection mold

2024-04-18

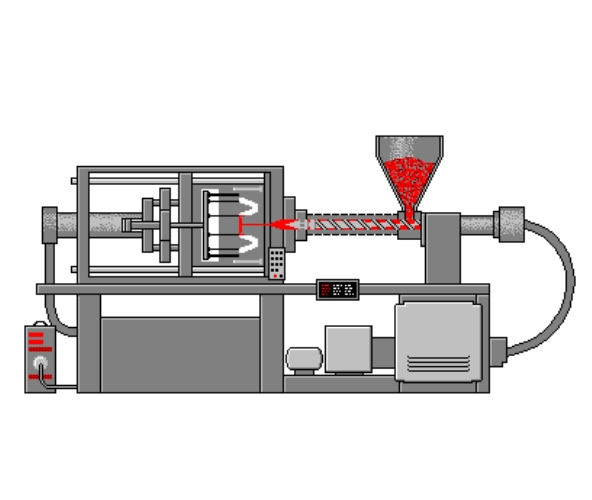

Isitofu sokungunda sisixhobo sokuvelisa iimveliso zeplastiki; ikwasisixhobo esinika iimveliso zeplastiki ubume obupheleleyo kunye nemilinganiselo echanekileyo. Ngenxa yokuba eyona ndlela iphambili yokuvelisa kukutofa iplastiki enyibilikisiweyo enobushushu obuphezulu kwi-mold ngoxinzelelo oluphezulu kunye ne-mechanical drive, ikwabizwa ngokuba yi-injection mold yeplastiki.

Icandelo:

I-1.Inkqubo yokugawula ibhekisa kumjelo wokuhamba kweplastiki kwi-mold ukusuka kwi-nozzle yomshini wokubumba inaliti ukuya kumngxuma. Iinkqubo zokuthulula eziqhelekileyo zenziwe ngamajelo aphambili, iziteshi zomgijimi, amasango, imingxuma yezinto ezibandayo, njl.

2.I-Lateral yokwahlula kunye ne-core pulling mechanism.

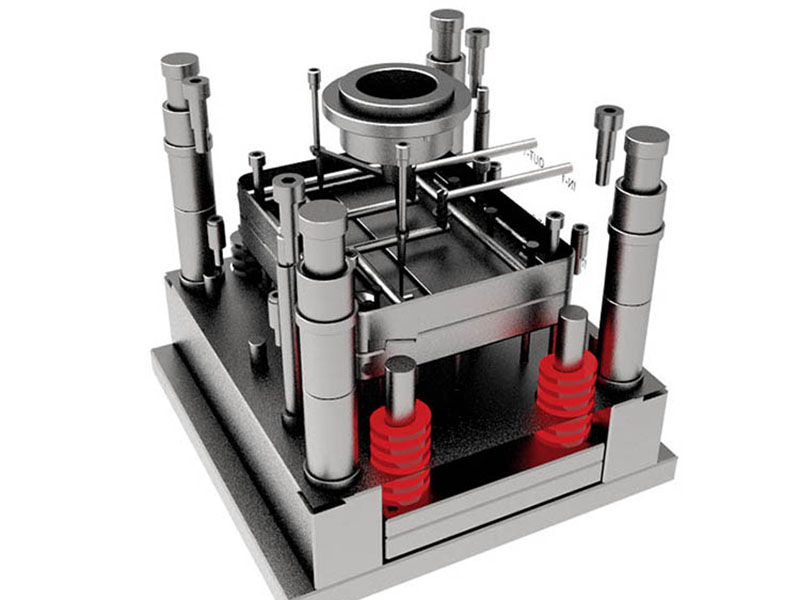

I-3.Indlela yesikhokelo kwi-mold yeplastiki ikakhulu inemisebenzi yokubeka, ukukhokela, kunye nokuthwala uxinzelelo oluthile lwecala ukuze kuqinisekiswe ukuvala ngokuchanekileyo kwe-molds ehambayo kunye nesigxina. Indlela yokudibanisa i-mold guide iquka izithuba zesikhokelo, imikhono yesikhokelo okanye imingxuma yesikhokelo (evulwe ngokuthe ngqo kwi-template), iicones zokubeka, njl.

4. Isixhobo se-ejection sidlala kakhulu indima yokukhupha i-workpiece kwi-mold, kwaye yenziwe yintonga ye-ejector okanye i-ejector tube okanye i-push plate, i-ejector plate, i-ejector fixed plate, i-reset rod, kunye ne-pull rod.

5. Inkqubo yokupholisa kunye nokufudumeza.

6. Inkqubo yokukhupha.

7. Amalungu abunjiweyo abhekisa kumalungu abumba umngxuma wokungunda. Ikakhulu ibandakanya: i-punch mold, i-concave mold, i-core, i-rod yokubumba, i-ring ring kunye nokufakwa kunye nezinye iindawo.

Ukuhlelwa:

Iimolds ze-injection zahlulwe zibe yi-thermosetting molds zeplastiki kunye ne-thermoplastic molds yeplastiki ngokweempawu zokubumba; ngokwenkqubo yokubumba, zohlulwe zibe yistamping mold tooling, ukudlulisa ukubumba, ukuvuthela ukubumba, ukubumba okutyhidiweyo, ukubunjwa kwe-thermoforming, kunye ne-hot mold mold, injection mold, njl.

Izinto:

Izinto zokubumba zichaphazela ngokuthe ngqo umphumo wokupholisa. Izinto ezisetyenziswa ngokuqhelekileyo zokubumba ziquka insimbi ye-P20, insimbi ye-H13, insimbi ye-P6, i-S7 insimbi, i-beryllium i-alloy copper, i-aluminium, i-420 insimbi engenasici, kunye ne-414 insimbi engenasici.

Umngxuma:

Umgodi wokungunda sisithuba esinemilo efanayo nemveliso ebunjiweyo eshiywe kubumba ukuze ifake iplastiki etyhidiweyo kwaye yenze imveliso emva kokubamba uxinzelelo kunye nokupholisa. Esi sithuba sikwabizwa ngokuba ngumgodi wokungunda. Ngokuqhelekileyo iimveliso ezincinci ezigqityiweyo ziyilwe njenge "multi-cavity molds" ngenxa yezoqoqosho kunye nokusebenza kakuhle. Umzekelo, umngundo unemingxuma emininzi yefilimu efanayo okanye efanayo ukuze ivelise ngokukhawuleza.

I-engile yoyilo:

I-engile yedrafti eqhelekileyo iphakathi kwe-1 ukuya kwi-2 degrees (1/30 ukuya ku-1/60). Ubunzulu malunga ne-1.5 degrees kwi-50 ukuya kwi-100 mm, kwaye malunga ne-1 degree kwi-100 mm. Iimbambo akufanele zibe ngaphantsi kwee-degrees ze-0.5 kwaye ubukhulu akufanele bube ngaphantsi kwe-1 mm ukuququzelela ukuveliswa kwesikhunta kunye nokwandisa ubomi bobumba.

Xa udibana nesidingo sokuthungwa, kucetyiswa ukuba i-angle kufuneka ibe nkulu kunemeko eqhelekileyo. I-angle enikwe yiyo kufuneka ibe ngaphezu kwe-2 degrees, kodwa i-angle akufanele ibe nkulu kune-5 degrees.

Isimbo esisisiseko:

I-mold-plate mold yeyona ndlela isetyenziswa ngokuqhelekileyo kwaye ineenzuzo zeendleko eziphantsi, isakhiwo esilula kunye nomjikelezo omfutshane wokubumba.

Inkqubo yomqhubi we-mold-plate mold ifumaneka kwi-plate yempahla. Xa i-mold ivuliwe, i-plate yempahla ikhupha inkunkuma kwi-runner kunye ne-bushing. Kwi-mold-plate mold, umgijimi kunye nemveliso egqityiweyo iya kukhutshwa ngokwahlukileyo.

Iintlobo eziqhelekileyo:

Ukunyathela isixhobo sokubumba sisixhobo esikhethekileyo senkqubo esisetyenziselwa ukusetyenzwa kwezixhobo zibe ziindawo ekusetyenzweni kwesitampu esibandayo. Ibizwa ngokuba yi-cold stamping die. I-Stamping yindlela yokucubungula uxinzelelo esebenzisa isikhunta esifakwe kwi-press ukuze ifake uxinzelelo kwizinto eziphathekayo kwiqondo lokushisa lokushisa ukuze kubangele ukuhlukana okanye ukuguqulwa kweplastiki ukufumana iindawo ezifunekayo.