0102030405

Ukuqedwa kobuso obujwayelekile bensimbi

2024-05-09

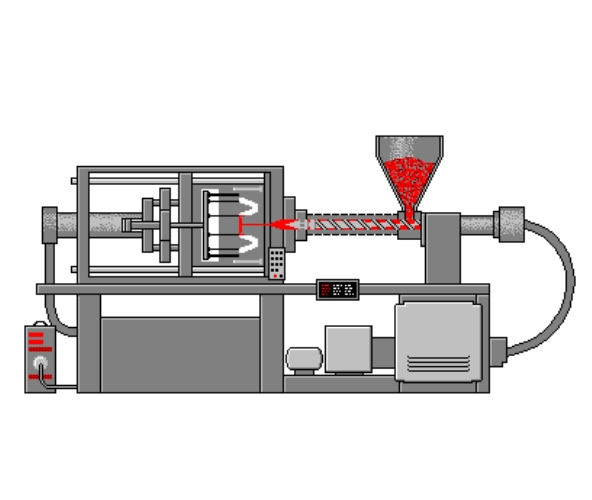

Izimboni eziningi, njengezezimoto kanye ne-aerospace, zithembele ensimbi ukuze zikhiqize izingxenye nezingxenye. Futhi uma kuziwa enkambisweni yokukhiqiza, ukuqedwa kweshidi lensimbi kungenye yezinyathelo ezibaluleke kakhulu okufanele uzicabangele.

Ukuqedwa kwensimbi yeshidi kuza ngezinketho ezihlukahlukene futhi ngayinye inezinzuzo nezakhiwo eziyibeka ihluke kwezinye. Ukufunda kabanzi ngazo kukwenza ukwazi ukukhetha okufanele iphrojekthi yakho elandelayo.

Okuqukethwe

1.I-Raw noma Emabi Qeda

2.I-Electroplating

3.Ukuqhunyiswa kobuhlalu

4.Anodizing

5.I-Electroless Plating

6.Powder Coating

7.Phosphate Coating

8.Electropolishing

9.Buff polishing

10.Abrasive Blasting

Qeda Okuluhlaza noma Okubi

Lolu hlobo lokuqedwa kwendawo yensimbi yeshidi kwenzeka lapho kungekho ukuqedwa okusetshenziswa kumkhiqizo oqediwe. Isiphetho esingahluziwe (ngezinye izikhathi esibizwa ngokuthi isiphetho esimahhadlahhadla) sivamise ukusetshenziswa uma impahla eyisisekelo isivele ifanele indawo ezosetshenziswa kuyo.

Isibonelo, kwezinye izimo, izinsimbi zensimbi engagqwali zisetshenziswa ngaphandle ngoba azikwazi ukugqwala futhi azidingi ukupholishwa okwengeziwe.

Ezinye izibonelo zokuqedwa okuluhlaza zifaka okokusebenza ezitshalweni zemithi namakhemikhali, ubucwebe, ama-air conditioner, nemiklamo yezimoto.

I-Electroplating

I-Electroplating iyindlela yokuqeda insimbi eyaziwa nangokuthi i-electrodeposition. Kuhilela ukusebenzisa olunye ungqimba lwensimbi (i-substrate metal) ebusweni beshidi lensimbi. I-substrate metal ivame ukuba lula noma ingabizi kakhulu futhi ifakwe egobolondweni elincanyana lensimbi. Lolu hlobo lokuqedela luvame kakhulu kumawashi agqitshwe ngegolide, amabhodwe etiye anesiliva, noma ompompi abafakwe ugesi nge-chrome.

Ukuqhunyiswa kobuhlalu

Ukuqhunyiswa kobuhlalu akunolaka kunokuqedwa kwe-sandblasting sheet metal. Ukuqhunyiswa kobuhlalu kusebenzisa isihlabathi noma ubuhlalu bengilazi ukuze kufinyelele isiphetho se-matte. Ngokuyinhloko isetshenziselwa ukususa noma yiziphi izimpawu zamathuluzi namabala. Ngakho-ke, ukufeza indawo efanayo futhi ejabulisa ngobuhle. Lokhu kuvamile ekuqedeni ezimotweni, phansi, namakhabetheni.

I-anodizing

I-Anodizing iyinqubo yokuqeda ingaphezulu lensimbi eyenza indawo ingagqwali ngenqubo ye-electrochemical. Iguqula ingaphezulu leshidi libe yi-oxide, elincanyana kakhulu kodwa elihlala isikhathi eside. I-Anodizing iyinqubo evamile yokuqedela insimbi yeshidi yokuqedwa kwezimoto nezingxenye zemishini. Ingase futhi ihlukaniswe ngezinhlobo ezintathu:

Thayipha I: Lolu hlobo ludala uqweqwe oluncane kodwa olumelana nokugqwala kusetshenziswa i-chromic acid.

Uhlobo II: Esikhundleni se-chromic acid, i-sulfuric acid idala isiphetho esiqinile nesimelana nokugqwala.

Uhlobo III: Ikhiqiza insimbi ewugqinsi, engagugi futhi imelana nokugqwala.

Izingxenye ze-anodized ziyabonakala ngaphakathi nangaphandle kwesakhiwo, izindlu zangasese, iminyango, amafasitela, nophahla.

(I-Anodizing)

I-Electroless Plating

I-Electroless Plating iyinqubo eyaziwa nangokuthi i-auto-catalytic noma i-chemical plating. Esikhundleni sezinto zikagesi, inamathisela insimbi ngamakhemikhali. Kuhilela inqubo yokubeka izinsimbi phezu kweshidi lensimbi ngokusebenzisa ukugeza kwamakhemikhali okunciphisa. Idala ukuncipha kwe-catalytic kwama-ion ensimbi anamathisela ingxenye. Ezinye zezinzuzo zayo zihlanganisa okulandelayo:

Idala isendlalelo esilinganayo

Inikeza ukuguquguquka kobukhulu nevolumu

Ihlinzeka ngokuqedwa okugqamile, okugqame kancane, nokucwebezelayo

I-electroless plating ingasetshenziselwa ama-brake pistons, izindlu zepompo, izifakelo zamapayipi, isikhunta sokujova, ukufa, isikhunta sokudla, nokunye okuningi.

I-Powder Coating

Ukugcoba ngempushana kungenye inqubo yobuhle lapho impushana eyomile ifafazwa ebusweni beshidi lensimbi. Isebenzisa inhlanganisela yama-modifiers, ama-pigments, nezinye izithasiselo ukuze kwakhiwe i-powder coating. Ngemuva kwalokho, insimbi yeshidi iyabhakwa ukuze kukhiqizwe amaketanga amade we-molecular, okuholela ekuxhumaneni kwe-cross-link. Lolu hlobo lokuqeda luvame ukusetshenziswa emishini yezimboni nasezintweni zasendlini

I-Phosphate Coating

I-Phosphate coating yaziwa nangokuthi i-phosphatization. Isetshenziswa kakhulu ezingxenyeni zensimbi ngokwelashwa ngamakhemikhali, lapho ungqimba olunamathelayo oluncane lukhiqiza ukunamathela okuqinile nokumelana nokugqwala.

I-coating yenziwe nge-zinc, iron, noma i-manganese phosphates. Umkhiqizo oqediwe ubukeka umpunga noma umnyama futhi uvame ukusetshenziswa embonini yezimoto.

I-Electropolishing

Le ndlela isebenzisa amandla kagesi ukuze ikhiphe ama-ion ensimbi engxenyeni yensimbi. Idala ukuthungwa kwendawo okubushelelezi nokucwebezelayo okwehlisa isikhathi sokuhlanza, ithuthukise ukumelana nokugqwala, isuse iziqongo nezigodi, futhi isuse imfucumfucu. I-Electropolishing iwusizo ezimbonini zokudla neziphuzo, ezokwelashwa, ezezimoto, zezinto zikagesi, nezimboni zefenisha.

Buff Ukupholisha

I-Buff polishing iyinqubo yokuqeda esetshenziselwa ukuhlanza nokushelela indawo yensimbi yeshidi. Isebenzisa umshini onesondo lendwangu.

Abakhiqizi abaningi futhi bayisebenzisela ukwakha ukubukeka okupholishiwe nokuhlobisa okukhangayo. Izimboni zemithi nezokudla zivame ukusebenzisa lolu hlobo lokuqeda.

I-Abrasive Blasting

Ukuqhuma okulimazayo kusebenzisa okokusebenza okuphezulu ukuze kusakazwe into elimazayo phezu kweshidi lensimbi. Yonga isikhathi nemali ngokuhlanganisa ukuqedwa kwendawo nokuhlanza.

Ngaphezu kwalokho, ingasetshenziswa njengendlela yokwelapha yokulungiswa kwendawo ngaphambi kokumboza, ukucwenga, noma ukudweba. Ezinye izimboni ezisebenzisa lokhu kuqedwa zihlanganisa ezezimoto, eziqoshiwe, ezokwakha, nokunye okuningi.

Khetha Inqubo Elungile Yokuzuza I-Best Sheet Metal Finish

Uhlobo ngalunye lokuqedwa kwensimbi yeshidi lunezinzuzo ezihlukile ezilwenza lulungele izinhlelo zokusebenza ezahlukene. Lapho ukhetha uzakwethu wokwenziwa kwensimbi , i-ABBYLEEE Tech inamandla angahlangabezana nezidingo zakho. Xhumana nathi namuhla, futhi sizokuqondisa ohlelweni lwethu.