Izinqubo ezivamile zokubunjwa kwepulasitiki

Enhliziyweni yemboni, ukunemba kanye nokuqamba okusha kuhlangene. Lapha, asigcini nje ngokubumba izimo, silolonga okungenzeka. Cabanga ngocezu lwezinto ezingavuthiwe eziguqulwa ubuchwepheshe zibe i-kaleidoscope yamathuluzi, izingxenye nemisebenzi yobuciko. Akuwona umlingo, ubuciko bokubumba umjovo.

Okulandelayo yizigaba ezijwayelekile zenqubo yokubumba ipulasitiki:

Ukubumba umjovo: Ukubumba umjovo, Faka ukubumba, ukubumba umjovo kabili, inqubo yokubumba umjovo wegwebu elincane, ukubumba umjovo we-Nano (NMT)

I-Blow Molding: I-Blow blowing, i-hollow blow molding (I-Extrusion blow molding, i-injection blow molding, i-Stretch blow molding)

I-Extrusion Molding

1.Ukubunjwa komjovo

(1)Ukubumba umjovo

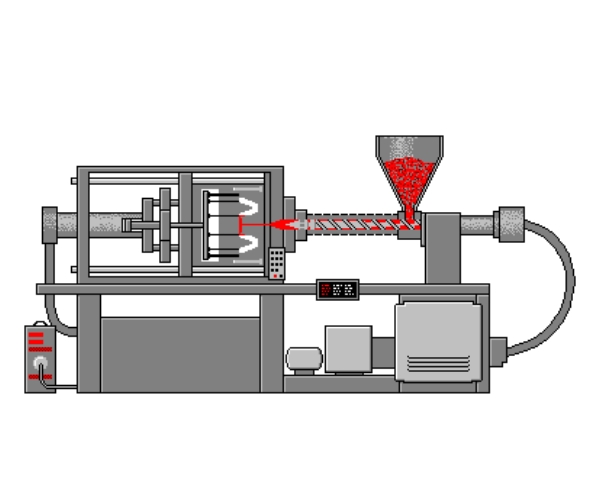

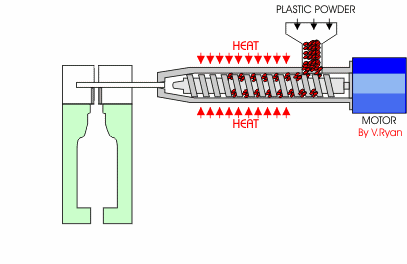

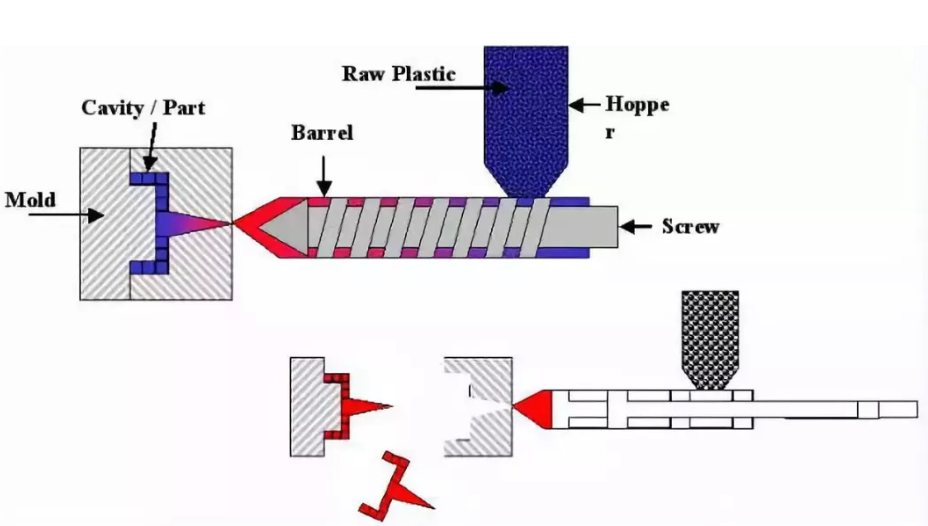

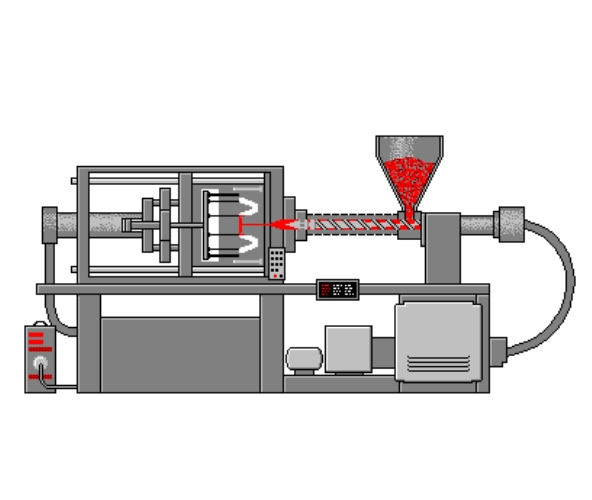

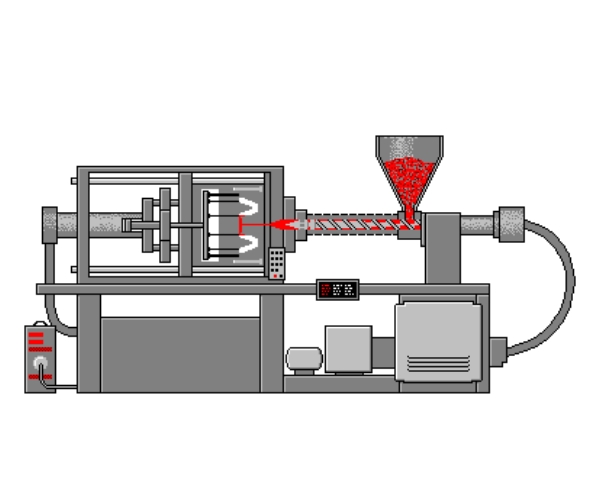

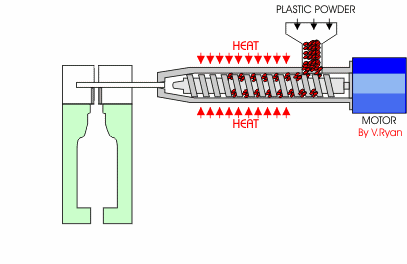

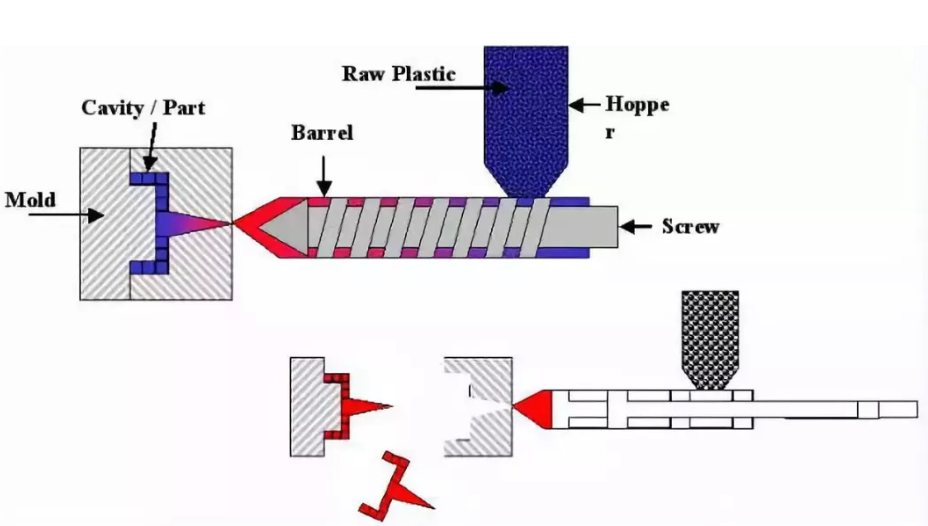

Ukubunjwa komjovo: Umgomo ukufaka izinto zokusetshenziswa eziyimbudumbudu noma eziyimpuphu ku-hopper yomshini womjovo, izinto ezingavuthiwe ziyashiswa futhi zincibilike esimweni esigelezayo, siqhutshwa yisikulufu noma ipiston yomshini womjovo, ngombhobho kanye nohlelo lokuthulula isikhunta emgodini wesikhunta, ukuqina nokubumba emgodini wokubumba. Izinto ezithinta ikhwalithi yokubumba umjovo: ingcindezi yomjovo, isikhathi somjovo, izinga lokushisa lomjovo.

Ubuchwepheshe Isici

Inzuzo | isici |

| 1.Sumjikelezo wokubumba we-hort, ukusebenza kahle kokukhiqiza okuphezulu, kulula ukufeza ukuzenzekelayo 2.Cifomu eliyinkimbinkimbi, usayizi onembile, ofake insimbi noma okungeyona insimbi yezingxenye zepulasitiki 3.Pikhwalithi ye-roduct izinzile 4.Uhla olubanzi lokuzivumelanisa nezimo | 1.Intengo yemishini yokubumba umjovo iphezulu 2. IIsakhiwo sesikhunta se-njection siyinkimbinkimbi 3. HIzindleko zokukhiqiza, umjikelezo omude wokukhiqiza, awufanele ukukhiqizwa kwezingxenye zepulasitiki zeqoqo elincane elilodwa |

IsiceloEmikhiqizweni yezimboni, imikhiqizo ye-ABBYLEE yokubumba umjovo wepulasitiki yilena: izinto zokwelapha, imikhiqizo yasendlini, izinto zasekhishini, igobolondo lezinto zikagesi (izomisa izinwele, izicoci zokuhlanza, iziqhumane zokudla, njll.), amathoyizi nemidlalo, imikhiqizo ehlukahlukene yemboni yezimoto, kanye nezingxenye zeminye imikhiqizo eminingi.

(2)Faka ukubumba

Faka ukubumba: Ukufaka ukubumba kubhekisela ekujovweni kwe-resin esibunjeni ngemva kokufakwa kwempahla ehlukene okulungiselelwe kusengaphambili, into encibilikisiwe kanye nokufaka ukuphulukiswa okuhlangene, okwenza inqubo edidiyelwe yokubumba umkhiqizo.

Ubuchwepheshe Isici

1. Inhlanganisela eyakhiwe ngaphambilini yokufaka okuningi yenza ukwakhiwa kwangemuva kokuhlanganiswa kweyunithi yomkhiqizo kube okunengqondo.

2. Ukwakheka okulula kwe-resin, ukugoba kanye nokuqina, amandla nokumelana nokushisa kwensimbi kunganezelwa ukuhlanganiswa kwemikhiqizo ehlanganisiwe yensimbi eqinile futhi eyinkimbinkimbi.

3. Ikakhulukazi ukusetshenziswa kokuhlanganiswa kwe-resin insulation kanye ne-conductivity yensimbi, umkhiqizo obunjiwe ungahlangabezana nemisebenzi eyisisekelo yemikhiqizo kagesi.

4. Ngemikhiqizo yokubumba eqinile, i-gasket yokuvala i-rubber emikhiqizweni egoqayo yokubumba i-elastic, ngokusebenzisa ukubunjwa komjovo we-matrix ibe umkhiqizo ohlanganisiwe, ingasindisa ukusebenza okuyinkimbinkimbi kokuhlela indandatho yophawu, okwenza kube lula ukuhlanganisa okuzenzakalelayo kwe-post-process.

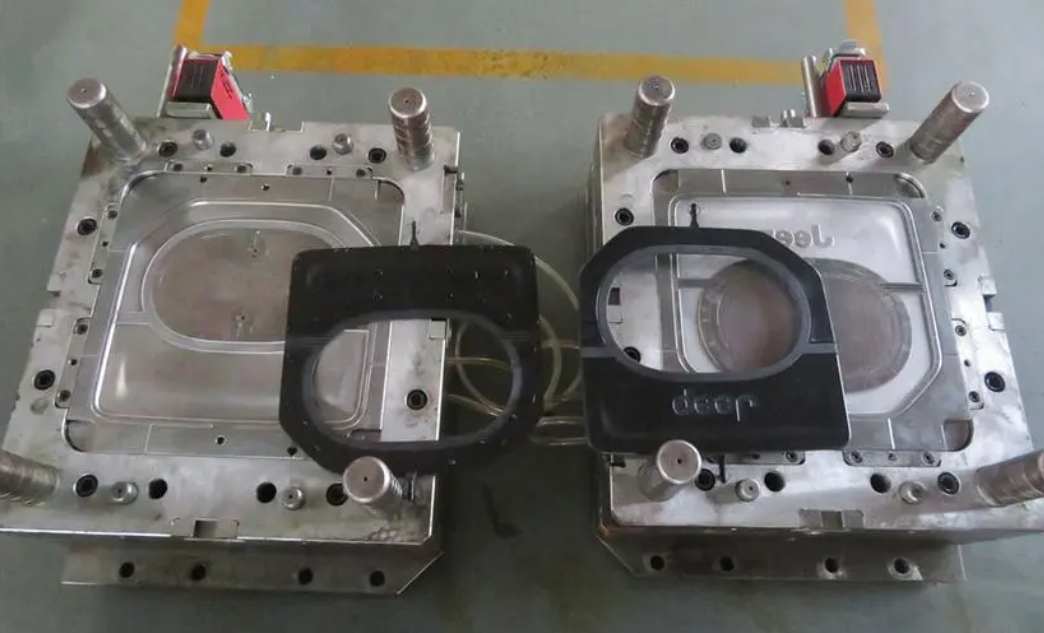

(3)Ukubumba umjovo kabili

Ukubumba komjovo kabili: kubhekisela endleleni yokubumba yokujova izinhlobo ezimbili zepulasitiki ezinemibala ehlukene esibunjeni esifanayo. Ingenza ipulasitiki ibonakale ngemibala emibili ehlukene, futhi ingenza izingxenye zepulasitiki zibonise amaphethini avamile noma amaphethini e-moire angajwayelekile ukuze kuthuthukiswe ukusebenza kanye nobuhle bezingxenye zepulasitiki.

Ubuchwepheshe Isici

I-1.Izinto eziyinhloko zingasebenzisa izinto eziphansi ze-viscosity ukunciphisa ingcindezi yomjovo.

2. Kusukela ekucatshangelweni kokuvikelwa kwemvelo, izinto eziwumongo zingasebenzisa izinto eziseceleni ezigaywe kabusha.

3. Ngokwezici zokusetshenziswa ezihlukene, njengempahla yesikhumba ewugqinsi eqediwe kusetshenziswa izinto ezithambile, izinto eziwumgogodla zisebenzisa izinto eziqinile noma izinto eziwumgogodla zingasebenzisa ipulasitiki yegwebu ukunciphisa isisindo.

4. Izinto eziyisisekelo ezisezingeni eliphansi zingasetshenziswa ukunciphisa izindleko.

5. Impahla yesikhumba noma into ewumgogodla ingasetshenziswa ebiza kakhulu futhi inezindawo ezikhethekile ezingaphezulu, njengokuphazanyiswa kwamagagasi kagesi, ukuhanjiswa okuphezulu nezinye izinto zokwandisa ukusebenza komkhiqizo.

6. Impahla yesikhumba efanele kanye nezinto eziwumgogodla zinganciphisa ukucindezeleka okusele komkhiqizo wokubumba, kukhuphule amandla emishini noma izakhiwo zomkhiqizo.

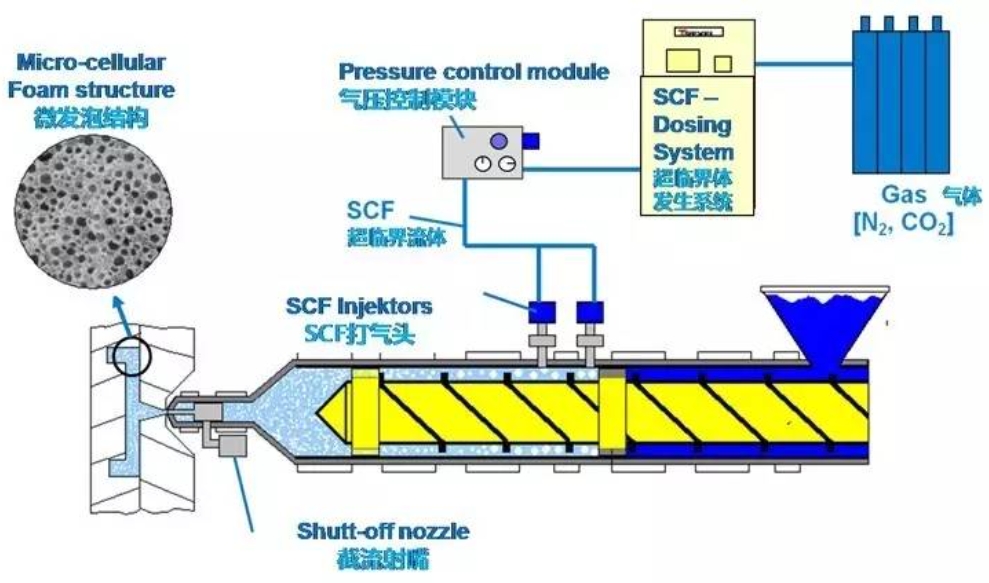

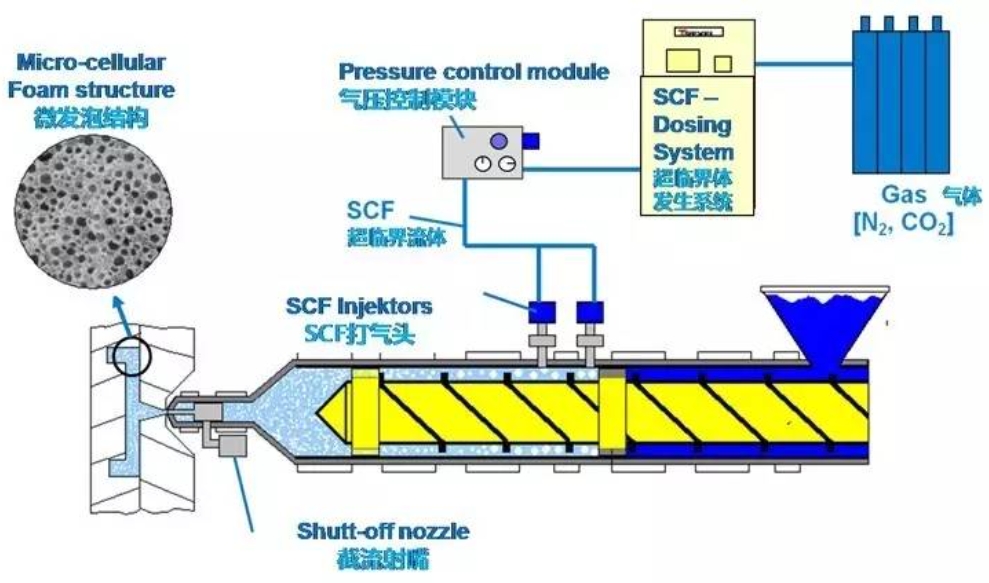

(4)Inqubo yokubumba umjovo wegwebu elincane

Inqubo yokubumba umjovo we-Micro-Foam: ubuchwepheshe bokubumba umjovo obunembayo obuncike ekwandeni kwezimbotshana ukugcwalisa umkhiqizo nokuqedela ukubunjwa kwengxenye ngengcindezi ephansi neyisilinganiso. Inqubo ye-microcellular foaming ingahlukaniswa ngezigaba ezintathu: okokuqala, uketshezi olunamandla kakhulu (i-carbon dioxide noma i-nitrogen) luhlakazeka ku-adhesive encibilikayo eshisayo ukuze kwakhe isixazululo sesigaba esisodwa; Khona-ke, ngokusebenzisa i-nozzle yokushintsha, isikhunta sesikhunta esinezinga lokushisa eliphansi nokucindezela siyajova. Ukuncipha kwezinga lokushisa nokucindezela kuholela ekungazinzini kwama-molecule, okwenza inani elikhulu lama-nuclei angamabhamuza emkhiqizweni, futhi lawa manuclei ebhamuza akhula kancane kancane abe izimbobo ezincane.

Ubuchwepheshe Isici

1.ukubumba umjovo ngokunemba.

2. ukweqa imikhawulo eminingi yokubumba umjovo wendabuko, kunganciphisa kakhulu isisindo sezingxenye, kufinyeze umjikelezo wokubumba.

3. ithuthukise kakhulu i-warping deformation kanye nokuzinza kwezingxenye.

Isicelo

Iphaneli yensimbi yemoto, iphaneli yomnyango, ipayipi le-air conditioning, njll.

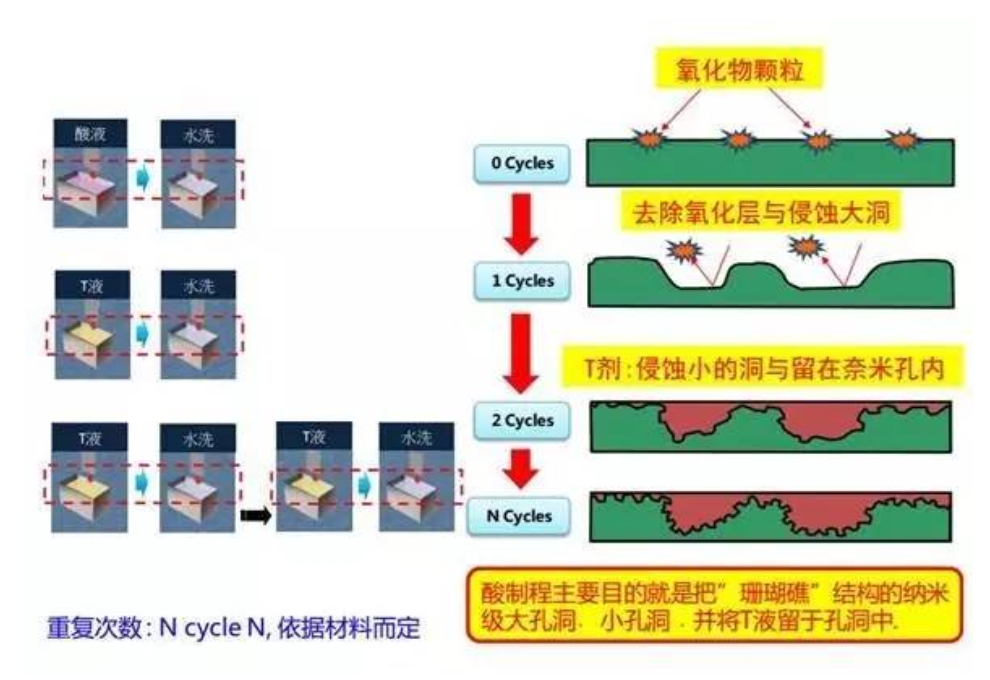

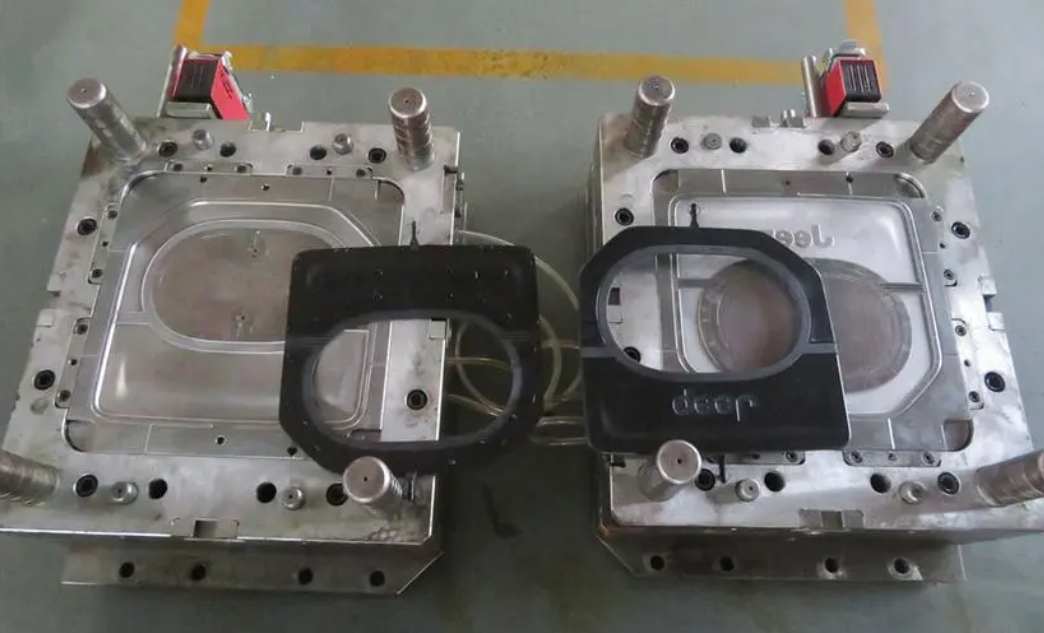

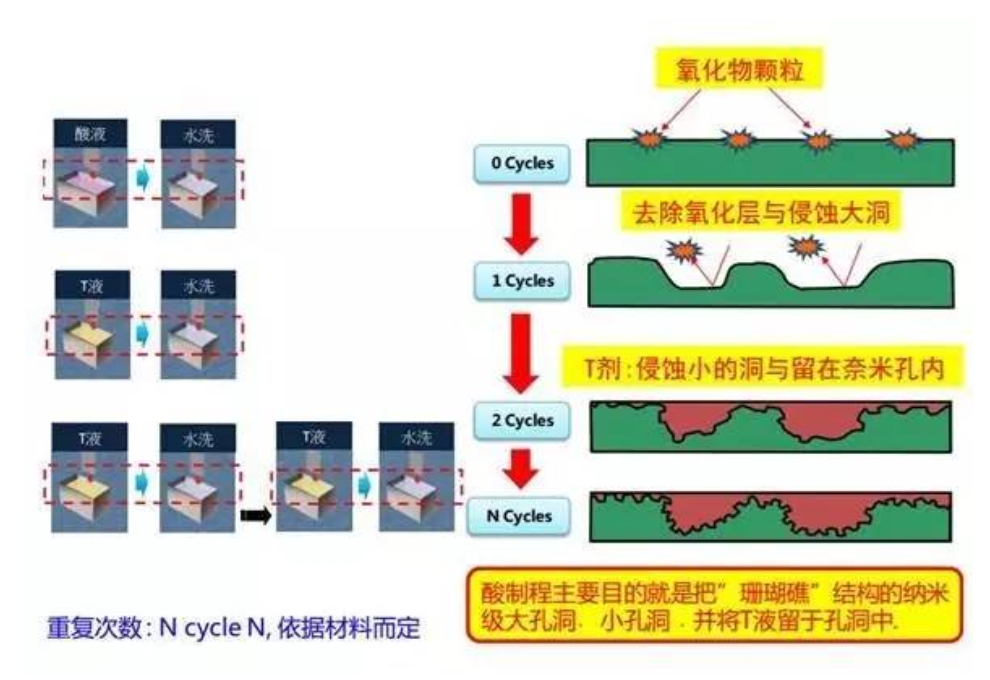

(5)I-Nano injection molding (NMT)

I-NMT(Nano Molding Technology): Iyindlela yokwakha yensimbi nepulasitiki ehlanganiswe ne-nanotechnology. Ngemuva kokuthi indawo yensimbi iphathwe nge-nano, ipulasitiki ijojowe ngokuqondile endaweni yensimbi, ukuze insimbi nepulasitiki yakheke njengento eyodwa. Ubuchwepheshe be-Nanoforming buhlukaniswe ngezinhlobo ezimbili zezinqubo ngokuya ngendawo yepulasitiki:

I-1.ipulasitiki yokungabonakali kokubumba okuhlanganisiwe

I-2.ipulasitiki yokubonakala kokubunjwa okuhlanganisiwe

Ubuchwepheshe Isici

1.Umkhiqizo unokuthungwa kokubukeka kwensimbi.

2.Ukwakheka kwendlela yomkhiqizo kwenziwa lula, okwenza umkhiqizo ube lula, ube mncane, ube mfishane futhi ube mncane, futhi ungabizi kakhulu kunendlela ye-CNC yokwenza.

I-3.Yehlisa izindleko zokukhiqiza namandla amakhulu okubopha, futhi unciphise kakhulu ukusetshenziswa kwezinto ezisetshenziswayo ezihlobene.

Izinto ezisebenzayo zensimbi ne-resin

1.I-Aluminium, i-magnesium, ithusi, insimbi engagqwali, i-titanium, insimbi, i-galvanized sheet, ithusi.

2.Ukuzivumelanisa nezimo kwe-aluminium alloy kunamandla, kufaka phakathi uchungechunge lwe-1000 kuya ku-7000.

3.I-resin ehlanganisa i-PPS, i-PBT, i-PA6, i-PA66, i-PPA.

I-4.PPS inamandla okuxhumana aqinile (3000N/c㎡).

Isicelo

Igobolondo leselula, igobolondo lelaptop, njll.

2.Blow Molding

I-Blow molding: Kuyindlela yokukhama impahla eluhlaza ye-thermoplastic encibilikisiwe isuka ku-extruder ingene esikhunjeni, bese ivuthela umoya endaweni eluhlaza, impahla eluhlaza encibilikisiwe yanda ngaphansi kwesenzo sokucindezela komoya, ingena odongeni lwesigxobo sesikhunta, futhi ekugcineni iphole futhi iqine ibe yisimo somkhiqizo oyifunayo.

Ukubunjwa kwe-Blow kuhlukaniswe ukubunjwa kwefilimu kanye nokubumba okungenalutho okuyizinhlobo ezimbili:

(1) Ukubumba ifilimu

Ukubumba ifilimu ukukhipha ipulasitiki encibilikisiwe isuka esikhaleni esiyindilinga somlomo wekhanda le-extruder ishone eshubhuni elincanyana eliyisilinda, kuyilapho kuphephuka umoya ocindezelwe embotsheni yeshubhu elincanyana embobeni emaphakathi yekhanda, kuqhunyiswa ishubhu elincanyana libe ifilimu eshubhu enobubanzi obukhudlwana (okwaziwa kabanzi ngokuthi ishubhu lebhamuza), bese uligoqa ngemva kokupholisa.

(2)ukubumba igalelo elingenalutho

I-Hollow blow molding ubuchwepheshe bokubumba besibili obuphephetha i-billet efana nerabha evalwe emgodini wesikhunta ibe yimikhiqizo engenalutho ngosizo lwengcindezi yegesi. Kuyindlela yokukhiqiza imikhiqizo yepulasitiki engenalutho. Izindlela zokukhiqiza zokubumba i-hollow blowing zihlukile, kufaka phakathi ukubunjwa kwe-extrusion blow, ukubumba i-injection blow kanye nokubunjwa kwe-stretch blow.

1) Ukubunjwa kwe-Extrusion blow:I-Extrusion blow molding iwukusebenzisa i-extruder ukukhipha i-billet ye-tubular, ukuyinamathisela emgodini wesikhunta bese umboza phansi ngenkathi kushisa, bese uvuthela umoya ominyanisiwe ungene emgodini we-tubula billet.

2) Ukubumba igalelo lomjovo:Okungenalutho okusetshenzisiwe kutholakala ngokubumba umjovo. I-billet ishiywe emgodleni wesikhunta, futhi ngemva kokuba isikhunta sivaliwe ngokubunjwa kokushaywa, umoya ocindezelwe udluliswa ngesikhunta esiyinhloko, i-billet ishaywa, ipholile, futhi umkhiqizo utholakala ngemva kokudilizwa.

Inzuzo

Ubukhulu bodonga lomkhiqizo bufana, ukubekezelelana kwesisindo kuncane, ukucubungula okuthunyelwe kuncane, ikhoneni lemfucuza lincane; Ifanele ukukhiqizwa kwenqwaba yemikhiqizo emincane emihle.

3) Ukwakhiwa kwe-Stretch blow:I-billet eye yashiswa ekushiseni okunwebekayo ifakwe ekubunjweni kokubunjwa, futhi ukunwetshwa kwe-longitudinal kwenziwa ngenduku yokwelula, futhi ukwelula okuphambene nokushaywa kwenziwa ngomoya ocindezelwe oshaywayo, ukuze kutholwe indlela yomkhiqizo.

Isicelo

I-1.I-Film blow blowing isetshenziselwa ikakhulukazi ukwenza ifilimu yepulasitiki.

I-2.I-Hollow blow molding isetshenziselwa ikakhulukazi ukwenza imikhiqizo yepulasitiki engenalutho (amabhodlela, imiphongolo yokupakisha, amathini okunisela, amathangi kaphethiloli, amathini, amathoyizi, njll.).

3.I-Extrusion Molding

Ukubunjwa kwe-Extrusion: kulungele ikakhulukazi ukubumba kwe-thermoplastic, kodwa futhi kulungele okunye ukugeleza okuhle kwe-thermosetting kanye nokubunjwa kwamapulasitiki aqinisiwe. Inqubo yokubumba iwukusebenzisa isikulufu esijikelezayo ukuze kushiswe futhi kuncibilike impahla eluhlaza ye-thermoplastic, iyikhiphe ekhanda ngomumo odingekayo we-cross-section, bese uphothula ngomumo, bese upholisa futhi usiqinise ngesipholile ukuze sibe umkhiqizo we-cross-section edingekayo.

Ubuchwepheshe Isici

1.Izindleko eziphansi zemishini.

I-2.Ukusebenza kulula, inqubo kulula ukuyilawula, kulula ukufeza ukukhiqizwa okuqhubekayo okuzenzakalelayo.

3.Ukukhiqiza okuphezulu kahle; Izinga lomkhiqizo lifana futhi liminyene.

I-4.Imikhiqizo noma imikhiqizo eqediwe yomumo wezigaba ezihlukahlukene ingakhiwa ngokushintsha ukufa kwekhanda.

Isicelo

Emkhakheni womklamo womkhiqizo, ukubunjwa kwe-extrusion kunokusebenza okuqinile. Izinhlobo zemikhiqizo ye-extrusion ziyipayipi, ifilimu, ibha, i-monofilament, itheyiphu eyisicaba, inetha, isitsha esingenalutho, iwindi, uhlaka lomnyango, ipuleti, i-cable cladding, i-monofilament namanye amaphrofayili.

Joyina i-ABBYLEE ukuze uhlole izimanga ezingapheli zokucubungula isikhunta sokujova futhi uvule inkathi entsha yokusungula.