Surface quality control of metal materials

Surface quality control of metal materials is very important in Machining. It can affect the service life, corrosion resistance and appearance of metal materials.

Common metal surface surface finishing

Many industries, such as automotive and aerospace, rely on Sheet Metal to produce parts and components. And when it comes to the manufacturing process, sheet metal finishing is one of the most important steps to consider.

Types of metal working processes

Metalworking processes are a series of processing methods used to change the shape, size or properties of metal materials. These processes can be roughly divided into cold forming, hot forming, casting, forging, welding and cutting processing and other categories.

Common materials used in metal processing

Methods for metal fabrication range in complexity with respect to the desired qualities of the end product and the composition of the materials in use. Strength, conductivity, hardness and resistance to corrosion are all commonly desired properties. Through varying techniques in cutting, bending and welding, these metals can be used in a variety of products ranging from appliances and toys, to larger structures like furnaces, duct-work and heavy machinery.

Injection mold cavity selection

Understanding the nuances of custom injection molding can be a daunting task, especially when it comes to deciding between single-cavity, multi-cavity, and family molds.

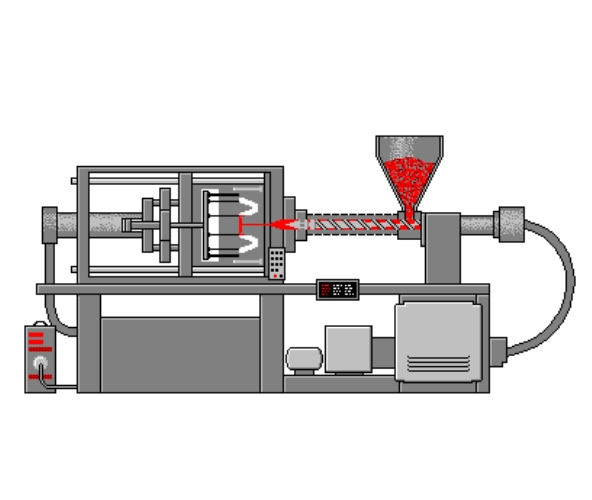

The composition mold cavity and application of injection mould

An injection mold is a tool for producing plastic products; it is also a tool that gives plastic products complete structure and precise dimensions. Because the main production method is to inject high-temperature melted plastic into the mold through high pressure and mechanical drive, it is also called a plastic injection mold.

Common processes for plastic molding

In the heart of industry, precision and innovation are intertwined. Here, we're not just shaping shapes, we're shaping possibilities. Imagine a piece of raw material transformed by technology into a kaleidoscope of tools, parts and works of art. It's not magic, it's the art of injection molding.

US Branch Set Up In US

During Abby and Lee's business trip to the US from January 10th to 20th, 2019, they successfully

Quality Control system in ABBYLEE Tech

ABBYLEE has strict quality control measures in place. Since 2019, ABBYLEE has obtained the ISO9001:2

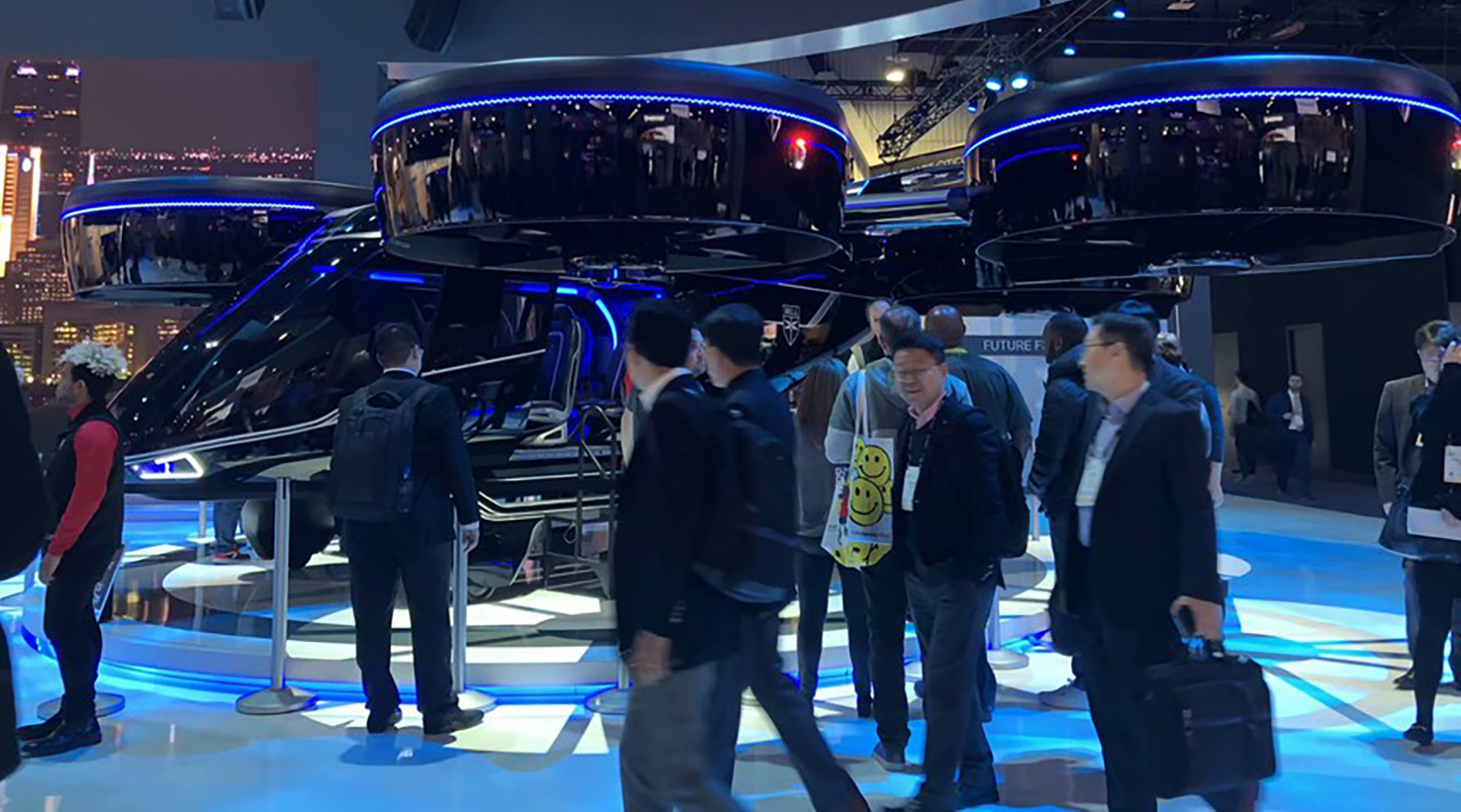

ABBYLEE Take Part In Ces Show,2019

On Jan 8th to Jan 11th, 2019 ,the founder of ABBYLEE Abby and Lee took part in CES show , Las vegas