OEM Injection Molding Plastic Parts Hight Precision Cryotube for Medical Using

We offer injection molding services for medical devices and medical equipment, providing custom ABS cases and support for other materials as well. Our one-stop service covers everything from design to production, allowing for seamless customization. Whether you need prototypes or mass production, we can accommodate any quantity requirement.

We hold ISO 13485 and ISO 9001:2015 certificates, Keyence measure Tooling and Dust-Free Injection Room and Assembly Room to control the quality of the medical devices and medical equipment.

OEM injection molding plastic parts precision cases for medical using

We offer injection molding services for medical devices and medical equipment, providing custom ABS cases and support for other materials as well. Our one-stop service covers everything from design to production, allowing for seamless customization. Whether you need prototypes or mass production, we can accommodate any quantity requirement.

We hold ISO 13485 and ISO 9001:2015 certificates, Keyence measure Tooling and Dust-Free Injection Room and Assembly Room to control the quality of the medical devices and medical equipment.

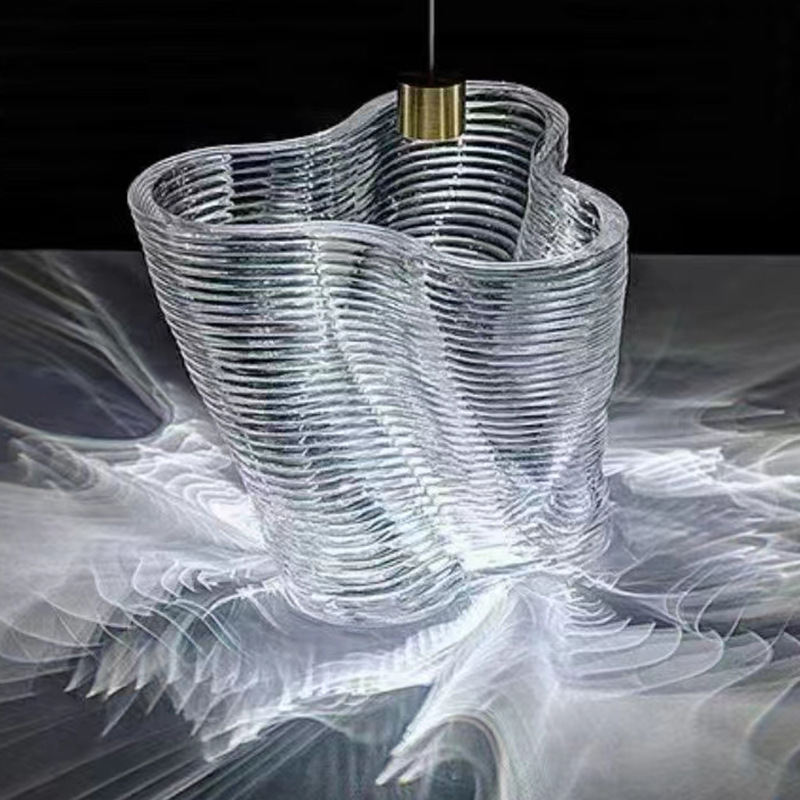

OEM injection plastic parts medicine bottles for medical using

We offer injection molding services for medical devices and medical equipment, providing custom ABS cases and support for other materials as well. Our one-stop service covers everything from design to production, allowing for seamless customization. Whether you need prototypes or mass production, we can accommodate any quantity requirement.

We hold ISO 13485 and ISO 9001:2015 certificates, Keyence measure Tooling and Dust-Free Injection Room and Assembly Room to control the quality of the medical devices and medical equipment.

OEM injection plastic parts pillminder case for medical using

We offer injection molding services for medical devices and medical equipment, providing custom ABS cases and support for other materials as well. Our one-stop service covers everything from design to production, allowing for seamless customization. Whether you need prototypes or mass production, we can accommodate any quantity requirement.

We hold ISO 13485 and ISO 9001:2015 certificates, Keyence measure Tooling and Dust-Free Injection Room and Assembly Room to control the quality of the medical devices and medical equipment.

Rubber Silicone Compression Tooling Parts molding manufacturing

Rich experience in molding manufactureing, equipped with automatic and intelligent advanced equipment, strict mold quality control, and diversified post-processing processes.

Rubber Silicone Compression Tooling Parts molding manufacturing

Rich experience in molding manufactureing, equipped with automatic and intelligent advanced equipment, strict mold quality control, and diversified post-processing processes.

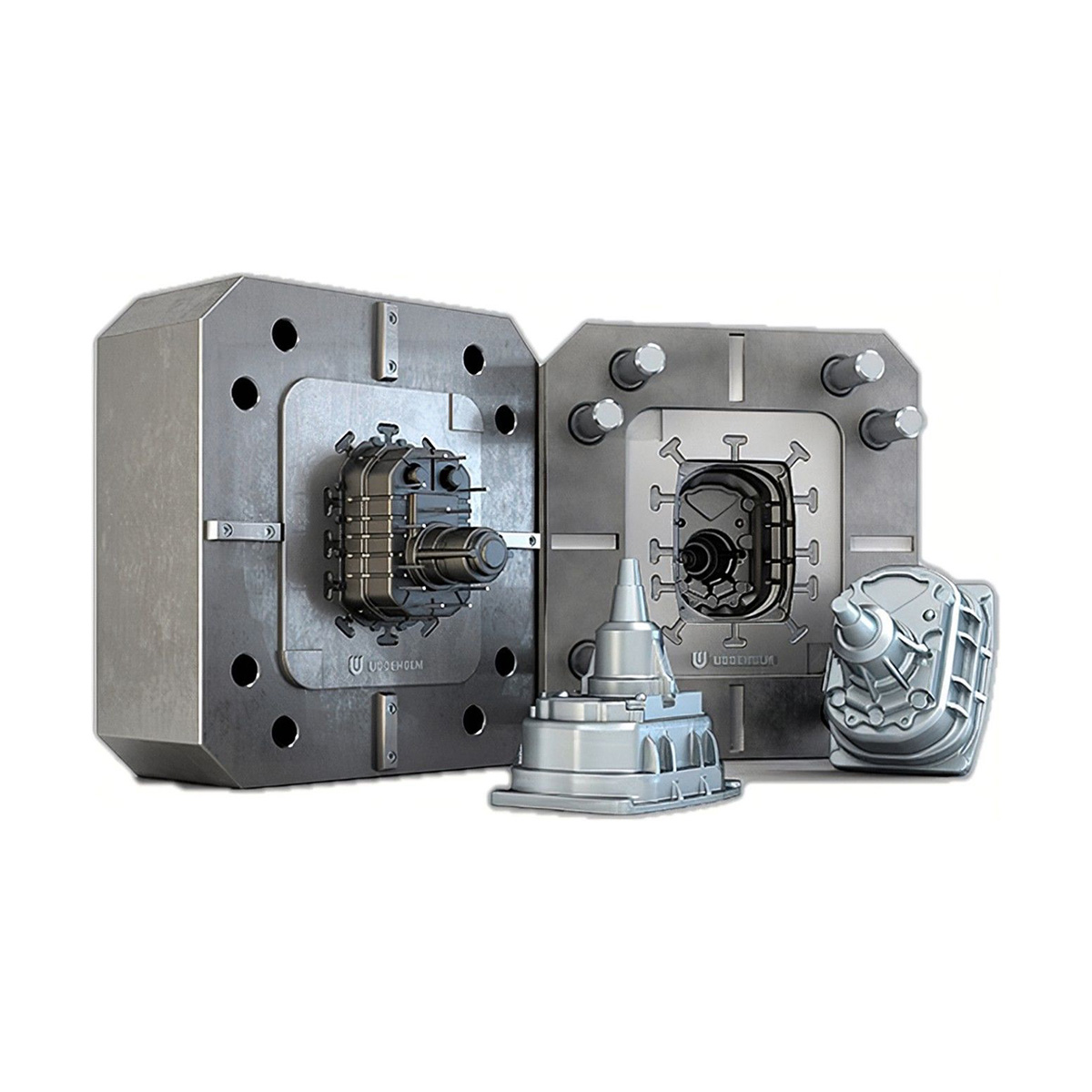

Custom Die Casting Mould Tooling products - die casting mould manufacturing

Die casting mold tooling at ABBYLEE refers to the process of designing and manufacturing molds or dies used in the die casting process. Die casting is a manufacturing method used to produce metal parts by forcing molten metal into a mold under high pressure.

The die casting mold tooling plays a crucial role in the die casting process as it determines the final shape, size, and quality of the casted parts. It is essential to have a high-quality mold tooling to ensure accuracy, repeatability, and efficiency in the die casting process.

Custom Die Casting Mould Tooling products - die casting mould manufacturing

Die casting mold tooling at ABBYLEE refers to the process of designing and manufacturing molds or dies used in the die casting process. Die casting is a manufacturing method used to produce metal parts by forcing molten metal into a mold under high pressure.

The die casting mold tooling plays a crucial role in the die casting process as it determines the final shape, size, and quality of the casted parts. It is essential to have a high-quality mold tooling to ensure accuracy, repeatability, and efficiency in the die casting process.

Custom Die Casting Mould Tooling products - die casting mould manufacturing

Die casting mold tooling at ABBYLEE refers to the process of designing and manufacturing molds or dies used in the die casting process. Die casting is a manufacturing method used to produce metal parts by forcing molten metal into a mold under high pressure.

The die casting mold tooling plays a crucial role in the die casting process as it determines the final shape, size, and quality of the casted parts. It is essential to have a high-quality mold tooling to ensure accuracy, repeatability, and efficiency in the die casting process.

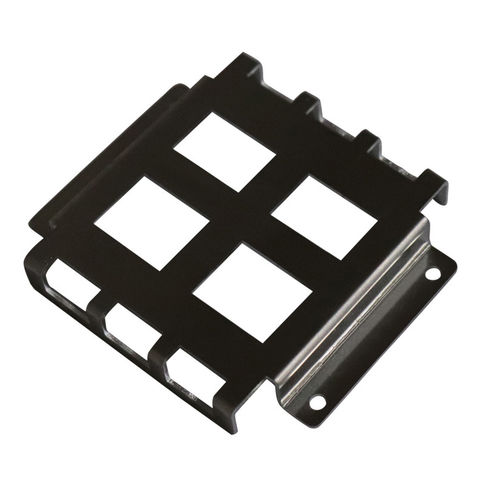

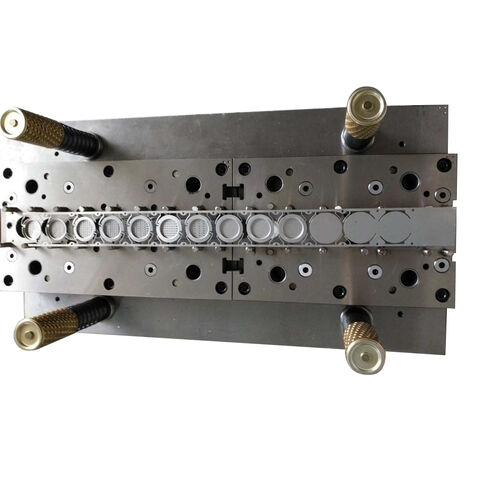

Customizable precision stamping molding press stamping die mold mould press die steel stamping molds

ABBYLEE can provide customers with high-quality and high-precision Stamping Mould Tooling. In terms of material selection, there is a wider choice for customers to choose from. In terms of precision, we have confidential processing equipment to ensure the accuracy of products.

Stamping Mold Professional Factory Custom High precision Industrial Metal China Punching Mold Stamping Die

ABBYLEE can provide customers with high-quality and high-precision Stamping Mould Tooling. In terms of material selection, there is a wider choice for customers to choose from. In terms of precision, we have confidential processing equipment to ensure the accuracy of products.

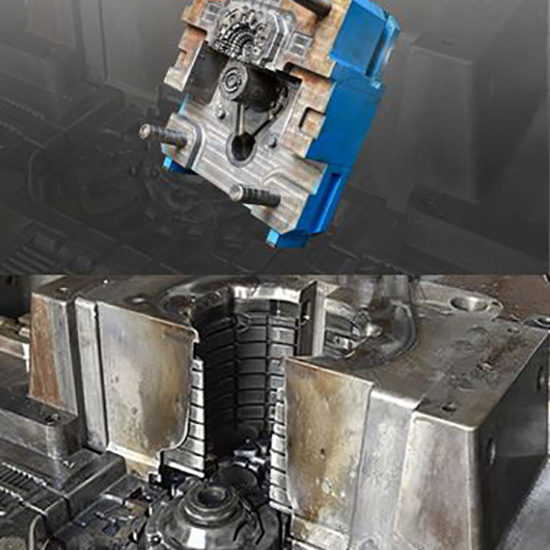

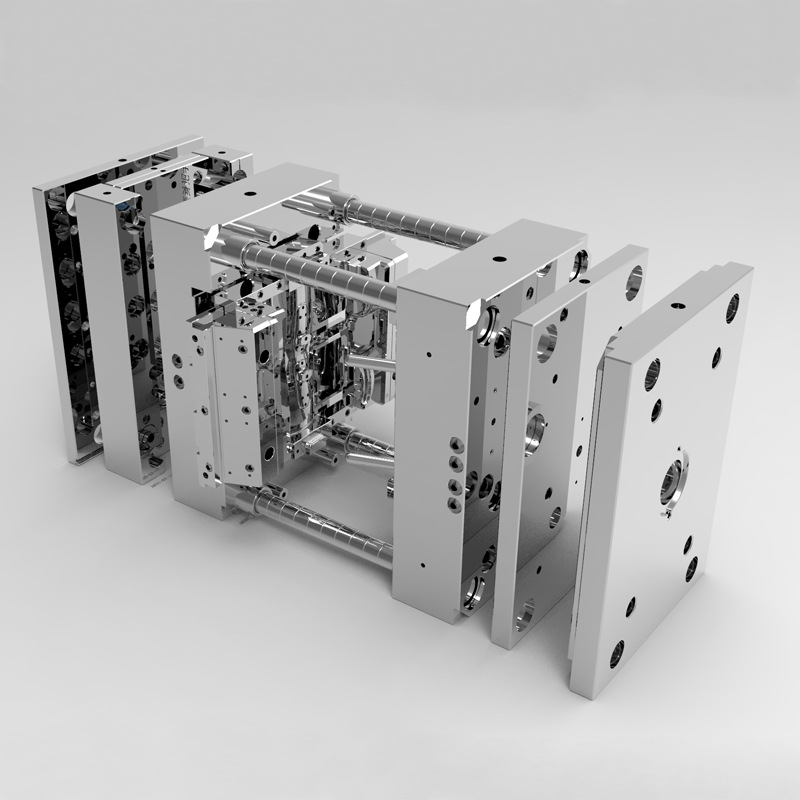

Abbylee Mould making-Injection mold

An injection mold at ABBYLEE is a tool used for plastic injection molding, which includes a mold shell and one or more mold cavities.

Injection molds usually include injection systems, cooling systems and ejector systems. The injection system is used to inject molten plastic material into the mold cavity. It includes an injection machine and a hot runner system. The cooling system is used to control the mold temperatue to ensure that the plastic material can solidify and cool quickly. Ejector systems are used to eject plastic products from the mold cavity.

The manufacturing process of injection molds usually includes design, processing, assembly and testing.

The accuracy and quality of mold manufacturing have an important impact on the shape and quality of the final product. Because injection molds have a high degree of complexity and precision, they are often used in mass production of automotive parts, home appliances, plastic containers, etc.

In the plastic products industry, injection molds are considered an important production tool, which can produce large quantities of plastic products efficiently and accurately.

Abbylee Mould making-Injection mold

An injection mold at ABBYLEE is a tool used for plastic injection molding, which includes a mold shell and one or more mold cavities.

Injection molds usually include injection systems, cooling systems and ejector systems. The injection system is used to inject molten plastic material into the mold cavity. It includes an injection machine and a hot runner system. The cooling system is used to control the mold temperatue to ensure that the plastic material can solidify and cool quickly. Ejector systems are used to eject plastic products from the mold cavity.

The manufacturing process of injection molds usually includes design, processing, assembly and testing.

The accuracy and quality of mold manufacturing have an important impact on the shape and quality of the final product. Because injection molds have a high degree of complexity and precision, they are often used in mass production of automotive parts, home appliances, plastic containers, etc.

In the plastic products industry, injection molds are considered an important production tool, which can produce large quantities of plastic products efficiently and accurately.

Custom sheet metal laser cutting parts fabrication

ABBYLEE can provide you with customized laser cutting services for the high-precision products required by customers. Laser cutting can process almost all metal. It can not only process high hardness and high melting point materials, but also process Brittle and flexible materials.

OEM Custom CNC Machining Metal Parts Assembly

The manufacturing of automotive plastic parts mainly uses materials such as PA66, SA, PP, PET, PMMA, and ABS. Parts that can be manufactured include signal light equipment, instrument panels, mirror boxes, fenders, air ducts, fans, wheel covers, and door and window components, etc.